Ballistic Resistant Glazing

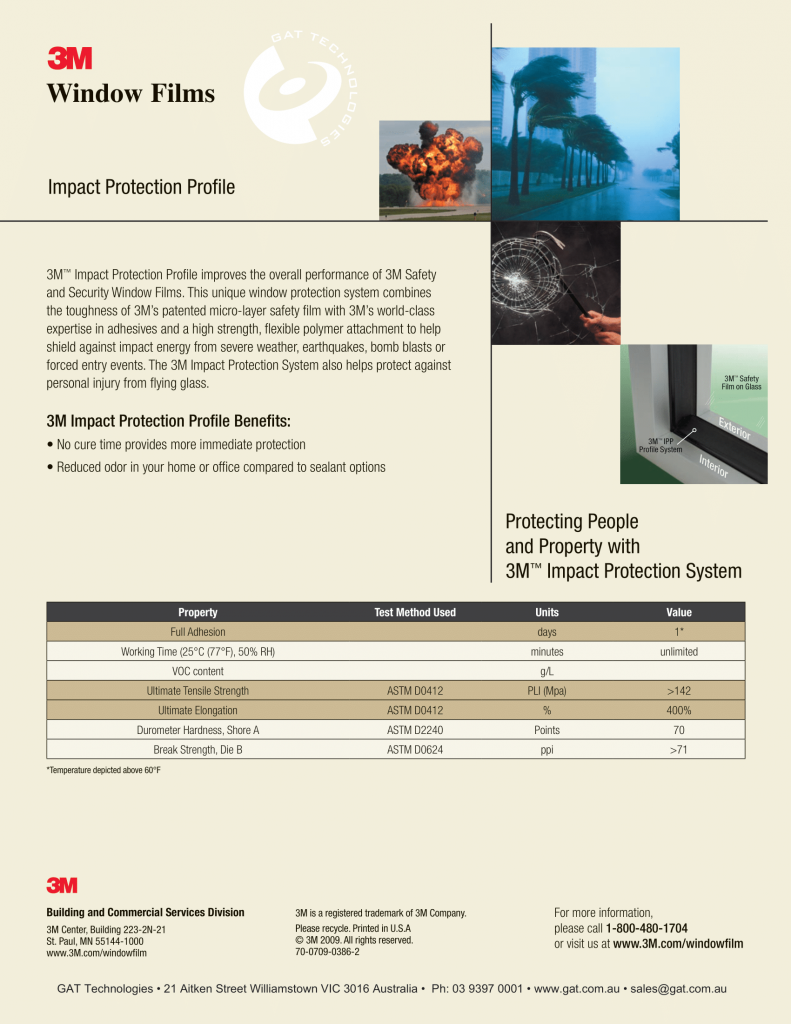

GAT Technologies Plastic Film & Sheet Solutions offer several bulletproof glass alternatives in the form of bullet-resistant plastic sheeting. Made from polycarbonate, our range is designed for high-security applications, such as security screens, protective windows for vehicles and businesses, and more. Discuss your needs with our team today and we can provide you with the product you need. We also offer large format CNC cutting/profiling, protective film lamination and large format digitizing, allowing us to customise our products to suit your specifications.

View Our Range

Our team members have extensive product knowledge and years of experience assisting clients, we can provide you with the products you need to keep business moving. Click on any of our products to learn more, or contact our team today and we can provide you with all the information you need.

Related Brands & Products

Click into the categories to check product details

What is Bullet Resistant Glazing?

Ballistic resistant glazing is also known as bulletproof glass alternative, bulletproof plastic, bulletproof window, bullet-resistant window, bullet-resistant screen, security screen plastic, and security shield. However, the correct term is ballistic resistant, as no manufacturer can guarantee complete protection from ballistics. The products we supply are rated for performance against ballistics as well as impact and forced entry, making them excellent for commercial and industrial applications. If you’re looking for specific features, discuss your needs with our team and we will connect you with the product you need.

FAQ

What is abrasion-resistant polycarbonate?

What are the benefits of using abrasion-resistant polycarbonate?

What applications are best suited for abrasion-resistant polycarbonate?

Can abrasion-resistant polycarbonate be cut and machined?

Is abrasion-resistant polycarbonate UV resistant?

Can abrasion-resistant polycarbonate be used for high-temperature applications?

Do You Want To Boost Your Business?

drop us a line and keep in touch

Call us today and a member of our team with specialised knowledge: Security Glazing, Intruder Resistant Glazing, Blast Resistant Glazing, Forestry Glazing, Mining Glazing will help you get what you’re looking for. We offer comprehensive after-sales support for all our products, ensuring you can make the most out of our services.